Mr. Alain SPOHR

Mr. Alain SPOHR

Managing Director, India & South Asia, Alstom

He joined Alstom from GE Energy India where he was the MD & CEO of the GE/Bharat Forge Join Venture and also the India Country Leader for Steam Power Systems. Mr Spohr brings with him over 35 years of experience in various roles in Country Business Leadership, Unit Management, Project Management, Engineering, Construction and Commissioning coupled with strong exposure to Industrial/factory operations. His rich career in India spans over 14 years which not only gives him a keen understanding on the countrys business environment but also its culture and growth trajectory.

Rail Analysis : Firstly, Congratulations on dispatching 100th coach from Sricity. Please tell us about the journey of Alstom in India till now. What are the key highlights of last six years?

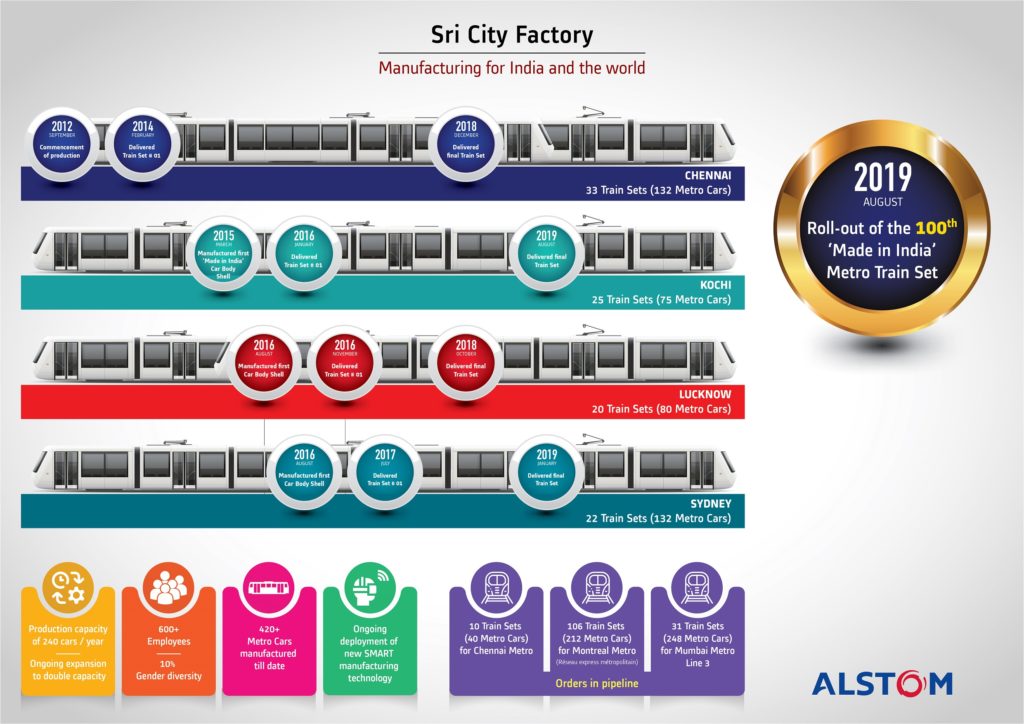

Mr. Alain SPOHR : Thank you. Indeed, a commendable feat and we are extremely delighted to achieve this landmark. While Alstom’s journey in India dates to the 1990s, our manufacturing journey in India kick-started with Chennai metro order in 2012. The contract led to the birth of the Sricity facility and was a game changer for the business as it was instrumental in establishing our presence as a rolling stock manufacturer in the country.

With Sricity, we wanted to build a state-of-the-art rolling stock manufacturing facility to cater to not just domestic but international projects. Six years since its inception, the facility today has aptly embodied both Alstom’s growth vision and world-class standards as well as government’s illustrious ‘Make in India’ ambition.

” Today, Sricity holds the feat of scoring a century! A 100 metro cars delivered to our happy customers across Lucknow, Kochi, Chennai and Sydney – our first export project. “

Back in 2014, when we delivered the first metro train set to Chennai Metro, the facility manufactured just 3-4 cars a month which was quickly ramped up to 20 cars a month. Going forward, we aim to double the production capacity.

All metro projects that we have worked on, allowed us to deliver custom-built solutions on-time. The credit goes to our 600+ strong team at Sricity, who have worked diligently to achieve this milestone.

India is strategic to Alstom’s operations. The domestic market is expanding steadily as well as factors of production—talent, material, facilities and policies—are also very supportive. For Alstom, this is an exciting time in the fast-growing Indian market.

Rail Analysis : You are supplying metro coaches for Mumbai Metro Line-3, which is India’s first fully underground metro line. What will make these coaches different from other Metro trains available in India? What type of new technologies you are introducing in these coaches (ex. Safety, Security and Comfort)?

Mr. Alain SPOHR : Mumbai is a global city and it requires a world-class, sustainable transport solution. Mumbai Metro Line 3 is Alstom’s biggest urban rolling stock order in India. We would be supplying our Metropolis trainsets for Mumbai Line 3. With its extensive track record, large range of configurations, low lifecycle costs and keen focus on the passenger experience, the Alstom Metropolis is a standard setter in reliable and attractive metro trains.

The Metropolis trainsets are configured precisely to suit customer’s requirements, be it length, width or seating arrangements. The solution is fully scalable, capable of working in multiple units or being lengthened by adding additional cars. Metropolis not only operates in driver mode but also driverless, spearheading a growing trend for automatic train operation (ATO).

Alstom is constantly at the cutting edge of innovation to reduce energy consumption, and Metropolis is no exception. Initiatives include full electrical braking, light weight design, highly efficient power converters, regulation of climate control according to passenger load, and LED lighting. Metropolis displays low lifecycle costs due to extended maintenance intervals and easier maintenance.

” Apart from these cutting-edge features, the Mumbai metro cars will also have 75% motorization, as stipulated by the Ministry of Urban Development guidelines. This will enable quick acceleration and deceleration thereby bringing about greater efficiency in operations. “

It will be also the first UTO (Unattended Train Operation) project in Mumbai and second in India.

Rail Analysis : Please brief us more about the contribution of Alstom in boosting ‘Make in India’ initiative. What kind of latest products for coaches & rolling stock Alstom looking to indigenize in India?

Mr. Alain SPOHR : ‘Make in India’ has given the manufacturing sector in India a boost and the Government’s openness to collaborate with other countries makes this a prodigious opportunity for businesses across the world. For India to continue to take giant strides in growth and development, it is imperative for the manufacturing sector to perform.

Alstom has always been a flag bearer of the ‘Make in India’ initiative. Be it our extensive manufacturing footprint – 3 manufacturing facilities, our talent base (4200 employees and growing) or the strong project references (Kochi, Chennai, Lucknow, Sydney, Mumbai Line 3 and Montreal), we are deeply committed to this vision and the subsequent outcome of this programme.

” Alstom has always had localisation at the heart of its operations. At Sri City all electrical components used in our metros are manufactured in our facility in Coimbatore and the remaining equipment sourced from suppliers in the country. The facility also delivered a fully indigenised Sydney Metro recently and is gearing up to deliver metros for Mumbai Line 3 as well as Montreal Metro. “

Bengaluru which is our Centre of Excellence for rolling stock, signalling and digital mobility engineering, is the second biggest engineering centre for the company after France. Right from Designing in India to Make in India, we are walking the talk.

The modern state-of-the-art Lucknow metro train sets with gen-next signalling system integrated across the network have been 100% made in India – designed in Bengaluru and manufactured out of Sricity plant.

The Kochi Metro project is another example of a 100% Made in India metro project where we executed end-to-end solutions ahead of schedule – power, tracks, signalling, rolling stock et al. We aim to continue to strengthen our presence in the region by leveraging our robust manufacturing and engineering capabilities based out of India.

Rail Analysis : Indian Railways is looking to buy ready-made trains from private companies instead of building them at its own production units. How Alstom seeing this opportunity and what are your plans for the same?

Mr. Alain SPOHR : The decision of Indian Railways to buy readymade trains from private players spells a big opportunity for players like us. Alstom draws on its technological expertise and innovative capabilities to meet the current and future needs of operators and passengers. Alstom has built an international reputation on the performance and technological lead provided by its transport solutions. As a leader in end to end transport solutions, we are well poised to tap such opportunities as and when it arises.

In fact, Alstom is already playing a key part in the Railways journey to transform rail transportation in the country and we would like to extend this association to other domains as well.

Rail Analysis : Is Alstom looking to ramp up its production capacity as many Metro projects at stages of under construction & planning in India?

Mr. Alain SPOHR : Yes, the Sricity factory is currently scaling up to double production capacity and introducing latest industrial technologies.

” This is in line with the company’s vision to establish India as an export hub along with the domestic projects. Given the massive opportunities in the metro space, we aim to bolster our industrial presence to respond to the growing needs of the market. “

Currently, our Sricity facility is gearing up to commence operations for Montreal and Mumbai Metro Line 3.

Rail Analysis : Tell us more about the 100th trainset roll out from Sricity? Why is this significant for Alstom?

Mr. Alain SPOHR : The rollout of 100th ‘Make-in-India’ trainset from Sricity facility is a landmark achievement for us. The delivery of the centurion trainset to Kochi Metro Rail Corporation Limited (KMRCL) also marks completion of the Kochi Metro order for 25 trainsets by Alstom. Kochi operates a 100% ‘Make in India’ metro fleet entirely custom-built at the flagship manufacturing facility at Sricity.

This milestone signifies many things, but most importantly, it is a vote of confidence of our customers in our capabilities to deliver world class, custom-made solutions.

This achievement has been possible by our belief in our Indian talent that includes more than 4200 team members working across various locations in India. We are confident to reach greater heights with our commitment to ‘Make in India’ and aligning our business goals with the country’s vision.