Context: Alstom has started deliveries of the 12000 HP, WAG-12B electric locomotives to Indian Railways, which is all set to revolutionise freight logistics in the country. The First WAG12B (12000 HP) locomotive operation started on Deen Dayal Upadhyaya (DDU) division on 18th May 2020. Built by Alstom, these WAG 12B engines are the highest-powered locomotives that will run on Indian rails. In line with the Government’s and Indian Railways’ target towards 100% electrification and towards sustainable mobility, this new WAG12B (12000 HP) locomotive will not only bring down operating costs for the Railways but will significantly cut down greenhouse gas emissions as well.

In continuation to their commitment towards Indian projects, Here is an exclusive interview with Mr. Alain Spohr, Managing Director India & South Asia, Alstom discussing about India’s first 12000 HP Electric Locomotive and other major projects in Indian market.

Interview Insights:

Rail Analysis: Firstly, Congratulations for the recent operations of Alstom’s 12000 HP Electric Locomotive by the Indian Railways. What are the new features Alstom has added in this new WAG-12B locomotive? How can these locomotives be a game changer in freight transportation in the Indian Rail sector?

Mr. Alain Spohr: Thank you for the warm wishes. It is a proud moment for all of us at Alstom as the country’s fastest and the most powerful electric locomotive built by us is being inducted into the Indian Railways’ freight service. This project is a game changer in bringing about an advanced and sustainable mobility solution for Indian Railways.

We are greatly excited about the journey that we have embarked with Indian Railways to manufacture India’s highest-powered electric locomotives. This revolutionary series will be redefining the freight services in the country. Alstom’s Prima T8 (designated as WAG12) will be India’s fastest and safest electric locomotives with 12000 HP, capable to haul ~ 6000 tonnes at a top speed of 120 kmph. Built at one of the country’s largest integrated manufacturing facility at Madhepura in Bihar, these locomotives are planned for deployment on the Dedicated Freight Corridors (DFCs).

Recent operations of 12000 HP Electric Locomotive by the Indian Railways

These electric locomotives will increase the average speed of freight trains in India by at least 20-25 kmph thereby reducing the congestion currently faced. This double-section, fully air-conditioned e-loco, is equipped with Insulated Gate Bipolar Transistors (IGBT) based propulsion technology that will amount to considerable savings in energy consumption.

Saharanpur depot also has a ‘Training Center’ equipped with a loco simulator and smart classrooms being used for skill development of railway employees. Till date, more than 500 loco pilots from Indian Railways have been trained and going forward, 500 will be trained annually.

Rail Analysis: What has been the journey for this project and some major milestones and moments? What are the expected timelines for delivery of the additional locomotives to the Indian Railways?

Mr. Alain Spohr: The journey till date has been extremely valuable for us. India is a unique nation, and all the learnings from here will only help improve our global competency. Partnering with Indian Railways, one of the largest Railway entities in the world is a matter of pride for us. The joint venture combines innovation with responsibility and together we are committed to deliver safe, reliable and efficient solutions.

As part of the largest Foreign Direct Investment (FDI) project in the Railway sector, Ministry of Railways (Indian Railways) and Alstom came together in 2015 to transform the heavy freight transportation landscape of the country. An agreement worth Euro 3.5 billion was signed to manufacture 800 fully electric super powered double-section locomotives for freight service and its associated maintenance over a period of 11 years. 100 e-locos are delivered annually for the next 8 years.

“ Our joint venture is one of the strongest realisations of Make-in-India vision in the railways sector. Designed at Alstom’s

Engineering Centre in Bengaluru, all e-locos are being manufactured indigenously at India’s largest integrated greenfield manufacturing facilities at Madhepura in Bihar. ”

As part of this project, we have set-up two maintenance depots at Saharanpur (Uttar Pradesh state) and Nagpur (Maharashtra state). The Nagpur depot is still in the construction stage. The Madhepura industrial site is built to international standards of safety and quality and project will create more than 10,000 direct and indirect jobs in the country – primarily in the states of Bihar, Uttar Pradesh and Maharashtra.

Manufacturing of 12000 HP Locomotive in Madhepura factory

The project is also defined by its highly localised supplier base. Almost 90% of the components used to manufacture these locomotives are being sourced locally.

Rail Analysis: In your perspective, what has been the Impact of the Covid-19 Pandemic on the Indian Rail & Metro Sector. What are the precautionary measures you have undertaken to resume your operations & what are the safety measures Alstom is following at the Manufacturing plants and at other sites?

Mr. Alain Spohr: Covid-19 has severely affected the global economy, especially the manufacturing industry. Despite the challenges over the past few months, at Alstom, we are certain about aligning our business strategies with people strategies. Our highest priority is the health and safety of our employees. At the same time, our commitments to the customers continues to be our focus area. We have put in place a detailed plan to meet our business commitments without compromising on safety standards as we resume operations.

All possible vulnerabilities have been mapped and due caution has been exercised. Our teams have embraced the new-norm and are adapting well. As we resume operations at our sites in a phased manner, we have a robust preparedness plan in place. We have relooked at our internal policies to suit the current situation and have mapped all possible touch points. All actions are aligned to the government’s guidelines.

Apart from providing logistical support, we are also ensuring all the safety measures are being taken across sites and offices. This include regular disinfection, mandatory use of masks, temperature screening at entry points, use of PPE kits for all staff etc. We are also taking measures to exercise social distancing across all

common areas and reducing seating capacity in our offices. Further, we are disinfecting the shop floor at regular intervals in addition to fumigating the premises periodically. Along with this, our shuttle buses are being disinfected before and after every trip.

Precautionary measures at Madhepura Factory

We have also arranged quarantine rooms at each office/ site. An emergency vehicle is also kept on standby across all our offices and factories. Apart from this, we are also working with our customers to ensure that their businesses are up and running effectively post the lockdown. Our commitment to the workforce and customers will continue to remain our priority as we navigate this period.

Rail Analysis: What is the status of the rolling stock of Mumbai Metro Line 3 project and what are the new innovations and features we can expect in these metro trains? When will Alstom begin supplying these trains to MMRC?

Mr. Alain Spohr: The Mumbai Metro Line-3 project is also one of the largest urban rolling stock order in India for Alstom. We commenced manufacturing metro trainsets from December 2019 at our world-class rolling stock manufacturing facility in Sri City, Andhra Pradesh. As per plan, the first metro train will be delivered this financial year.

Designed on the theme of ‘Dynamic Fluidism’, the metro draws its inspiration from the city. The metro train prioritises high interior density layout to maximise space efficiency. The trainsets are custom designed for Mumbai and will be able to accommodate at least 3000 people on a single trip, easing daily commute. The Aqua Line trainsets will also feature a host of safety elements including CCTV cameras, smoke detectors, emergency intercoms, fire extinguishers with wider detrainment doors to quickly evacuate passengers in case of an emergency. The inclusive design of trainsets will serve to the specially abled individuals with ease of travel and includes dedicated space for wheelchair in every car.

Start of production for Mumbai Metro Line 3

Along with the rolling stock, Alstom is executing the power supply contract and equip Line 3 with Urbalis 400, the latest generation of CBTC signalling technology. The scope of the signalling contract includes unattended train operation (UTO), computer-based interlocking and centralised train supervision; an integrated telecom solution comprising of CCTV, passenger information, passenger announcement and Gigabit network; platform screen doors, as well as the electrical and mechanical supervisory control and data acquisition system (E&M SCADA).

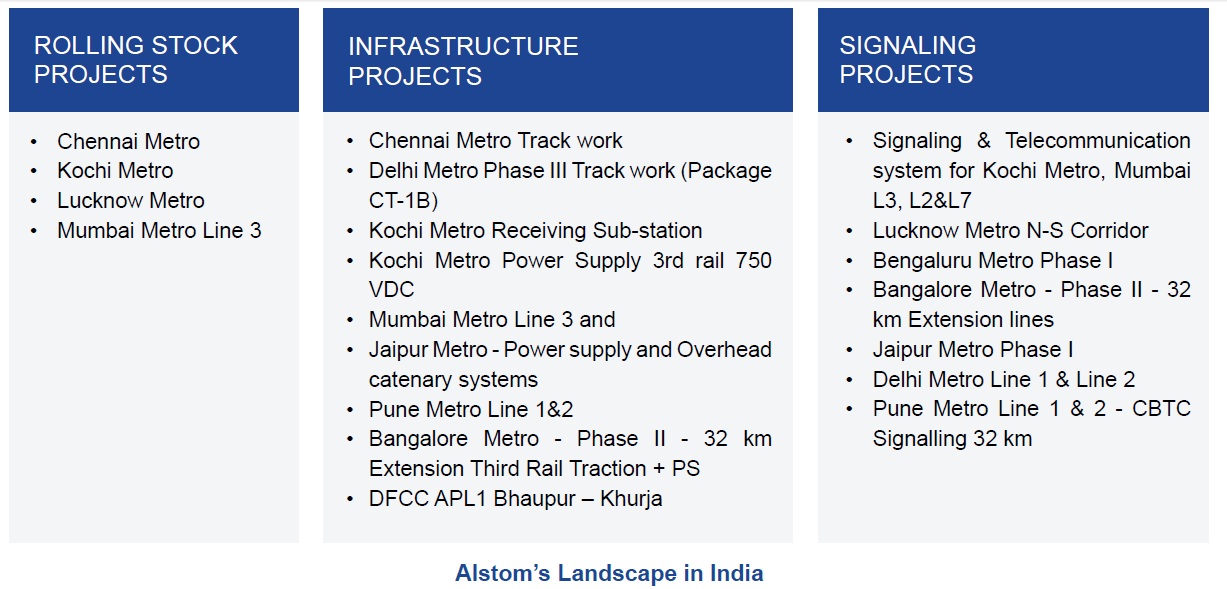

Rail Analysis: Please share the updated footprint of Alstom in the Indian market for rolling stock, signalling and other initiatives in the Railway & Metro Sector?

Mr. Alain Spohr: Alstom has established a significant presence in India. Today, we employ more than 5,500 people full-time. In-line with Government of India’s Make-in-India initiative, we have been investing heavily in the country to produce world-class rolling stock and components and delivering engineering services to various global sites.

Alstom is also executing electrification, signalling and telecommunications system for over 343 km along the Eastern phase of the ambitious Dedicated Freight Corridor which is a key step in transforming the freight services in the country. As part of the contract, Alstom is building the sub-stations and providing the control centre. The control centre situated at Allahabad is World’s second largest Operations Control Centre for the entire length of the Eastern Dedicated Freight Corridor. The Dedicated Freight Corridor (DFC) will not just enable safer and timely movement of freight across the country but will also reduce the traffic on the corridor for passenger trains.

As you are aware, as part of the e-loco project, we have also set up one of India’s largest greenfield facilities in Madhepura. This project also includes setting-up of two maintenance depots at Saharanpur (Uttar Pradesh state) and Nagpur (Maharashtra state).

Alstom in India not only caters to domestic needs, but also delivers engineering, components and fully built trainsets for various countries across the globe.

Alstom’s Sri City (Andhra Pradesh) factory is a state-of-the-art manufacturing unit for Urban Rolling Stock.

- Alstom’s SriCity (Andhra Pradesh) factory is a state-ofthe- art manufacturing unit for Urban Rolling Stock. The export projects from this factory include:

- Sydney metro North West Line, Australia: 22 units X 6 car each Metropolis train

- MRéseau express métropolitain (REM), Montreal, Canada: 106 units X 2 car each completely automatic light-metro system

- Sydney Metro City and Southwest, Australia: 23 units X 6 car fully automated Metropolis trains

- Alstom’s factory in Coimbatore (Tamil Nadu) is a modern facility for rolling stock components that specialises in designing, manufacturing and testing traction and electrical components. This factory exports to many countries including France, Belgium, Italy and Poland.

Alstom’s factory in Coimbatore (Tamil Nadu) is a modern facility for rolling stock components that specialises in

designing, manufacturing and testing traction & electrical components.

- The engineering centre is Bengaluru (Karnataka) is the largest one for Alstom, outside of France, and delivers projects for many global sites.

Rail Analysis: What is the status of acquisition of Bombardier Transportation by Alstom? How will this acquisition be a game changer in the global rolling stock market?

Mr. Alain Spohr: Alstom announced on February 17, 2020 that it had signed a Memorandum of Understanding with Bombardier Inc. and Caisse de dépôt et placement du Québec (“CDPQ”) in view of the acquisition of Bombardier Transportation. Alstom’s unions indicated they will render their opinion around summer 2020 on the proposed takeover of Bombardier Transportation, according to the “method agreement” reached with management. An EGM vote on the reserved capital increases to CDPQ and Bombardier Inc. and the rights issue should take place no later than October 31, 2020. Subject to the EGM approval, rights issue will take place between the second semester 2020 and first semester 2021, subject to market conditions, and the reserved capital increases will take place at closing.

“ The syndication of €2.4 billion of Bridge Facilities and a new €1.5 billion Revolving Credit Facility related

to the proposed acquisition of Bombardier was completed in April 2020 as planned. ”

The transaction will also be subject to clearance from relevant regulatory authorities and anti-trust authorities. Closing is expected in the first half of 2021.

Rail Analysis: Congratulations for receiving multiple Prestigious Honors at the Rail Analysis Innovation & Excellence Summit 2020. Please share your experience at the summit? How will this event contribute to the growing Indian rail industry?

Mr. Alain Spohr: It’s indeed a great experience being at the summit alongside some of the well-know personalities from Railways and other industry majors. We are thankful to your team for hosting Rail Analysis Innovation & Excellence Summit 2020 and recognizing our work in transforming the mobility landscape of the country. The event brought together the industry leaders who are redefining rail transportation in India, and we look forward to contributing to the same in the future as well.

Rail Analysis: Any additional insights you would like to add for our readers?

Mr. Alain Spohr: The projects that we are currently working on plays a crucial role in transforming India’s mobility solutions in the most sustainable manner. It will help Indian Railways in moving a step closer to the goal of Green Railways and subsequently reducing the carbon footprint. With the sustainable yet innovative products and services that Alstom offers, we wish to be a preferred partner for Indian projects, both in Mainline and Urban.

This Interview is a part of our June 2020 Magazine: Subscribe to our Magazine Today!