INNOVATIONS TO ENHANCE GLOBAL RAIL SAFETY

Around the world, railroads continue to serve as a primary solution for effective hauling. While today’s rail industry priorities have become even more attuned to maximizing productivity and availability, safety remains a key factor. Through fleet modernizations, track structure improvements and technology advancements, such as asset protection and predictive maintenance tools, railroads are taking efficiency, safety and reliability to the next level. As a Caterpillar company, Progress Rail remains committed to our customers – having built a legacy on delivering superior value in a cost effective manner. Our team works hard to create lifelong relationships, supplying comprehensive rolling stock and infrastructure solutions for the global rail industry and setting the standard for excellence. Throughout our history, our iconic product portfolio has been at the forefront of railroad innovation. Our powerful data analytics platform, energy management suite, infrastructure inspection solutions and other technologies contribute not only to reducing the railroads’ total cost of ownership, but also making great strides toward improving overall safety.

Progress Rail offers a broad range of innovations to enhance global railway safety:

ASSET PROTECTION

PowerView

Our train inspection systems have a wide range of track-mounted equipment to aid in defect detection, diagnostics and monitoring. From protecting the ties and track to high value assets, Progress Rail can design an asset protection solution to meet customer needs.

The company also offers a state-of-the art grade crossing obstacle detection system, where through the use of radar, the system can detect objects in the intersection of road and track, and alert the operator, or in some cases, stop the train automatically.

In addition to wayside products, PowerView is a next-generation, crash-hardened Locomotive Event and Video Recorder.

It provides synchronized recording and playback of multiple data sources and can replace multiple locomotive recorders into a single unit.

It is also a complete processing platform that supports edge computing for local analytics, alarming and other applications. PowerView integrates across most OEM locomotive types, as well as various third-party systems.

REAL-TIME DATA FROM CAB TO CABOOSE

Progress Rail’s End-Of-Train (EOT) devices transmit real-time, vital information from the end of the train to the locomotive cab by way of a locomotive head of train device or locomotive control unit. This technology contributes to improved operational safety, accident investigation, security and vandalism prevention. Compared to other products available today, Progress Rail EOT devices offer a more modern design with improved reliability, ergonomics, lighter weight and advanced power management. The end of train coupler mount makes an EOT faster and safer to apply — a characteristic train operators can appreciate.

LOCOMOTIVE REMANUFACTURING

Progress Rail End-Of-Train (EOT) device

Progress Rail provides a full range of locomotive options, from new freight and passenger locomotives to remanufactured, modernized or overhaul options. The company is an industry leader in locomotive rebuilds and modernizations, having rebuilt or modernized many models in the last 10 years. Progress Rail has the ability to modernize an extensive line of locomotives, from switchers to line haul locomotives, and in recent years, has witnessed interest in rebuilding locomotives of all sizes. Progress Rail performs overhaul work at its Patterson, Georgia; Mayfield, Kentucky; Muncie, Indiana; and Tacoma, Washington, facilities in North America and at other locations around the world, including facilities in Europe. One of the company’s key differentiators is that Progress Rail serves an integrated locomotive manufacturer with the largest range of engines available for the rail market – spanning from two- to four-cycle options with anywhere from 750 to 6,000 horsepower.

What exactly is done to the locomotive?

Narrow Flash Butt Welder

Progress Rail offers a wide range of options to meet customer needs for modernizations or rebuilds. These options include improving emissions, increasing horsepower, implementing advanced electronics or fuel saving technologies, improving tractive effort and enhancing safety performance, as well as other solutions. Our goal is to customize a package to meet the individual customer’s needs and budget. Many customers determine rebuild/modernizations create the best life cycle cost scenario to meet their fleet needs.

As an example, for railroads that wish to modernize, we are able to implement the latest technologies. We offer complete Energy Management solutions to assist with fuel economy, or predictive analytics through our PR Uptime® Suite to ensure mission reliability and less downtime, as well as safety enhancements – for instance, through our Fatigue and Distraction Monitoring technology

TRACKWORK

Capabilities that Progress Rail offers for global rail infrastructure

Progress Rail has the most globally diverse shared knowledge base of track designs, technologies and innovations in the world – with design and manufacturing facilities in Europe, America and Australia. Progress Rail can customize and manufacture turnouts and track components to suit customer requirements, site specific conditions or network parameters as required. Progress Rail is an industry leader in track and track components, including proven experience with global railways, ranging from lighter networks to supporting some of the heaviest axle loads in the world. Progress Rail has one of most extensive infrastructure product and service portfolios available globally.

Our facilities offer products including fasteners, ties, anchors, direct fixation components, buffer stops, turnouts, switches and crossings – all customizable to meet customer needs and requirements. Progress Rail also manufactures Kershaw® Maintenance-of-Way equipment, such as Ballast Regulators, tie replacers and vegetation management machines, along with Flash Butt Welding machines to maintain rail infrastructure. Progress Rail is a leader in Flash Butt Welding technology, with replacement rail welding components also available.

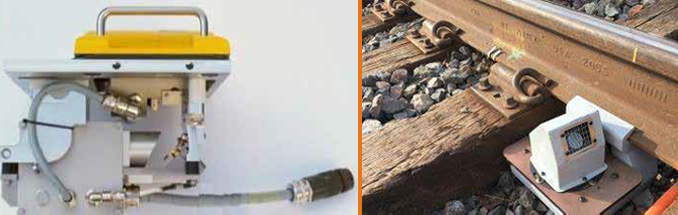

Progress Rail Signaling Asset Protection and Condition Monitoring technologies.

Progress Rail’s Asset Protection and Condition Monitoring systems are in use on multiple global rail lines. From software systems that gather information, raise alerts based on pre configured parameters and monitor wayside system health, to actual monitoring equipment such as Hot Wheel and Hot Bearing Detection, Dragging Equipment Detection and Acoustic Bearing Monitoring, the company offers multiple innovations to help keep assets secure.

Progress Rail’s equipment and software are in use on many railways, and the company directly interfaces with other signal providers ranging from Positive Train Control to the asset protection systems. Progress Rail also has experience with most major contracting companies and has a reputation for delivering quality product on time and on budget.

Progress Rail can provide full turnkey packages for the Asset Protection and Condition Monitoring systems. This can include, but it not limited to:

- Design

- Procurement

- Supply

- Installation

- Interface with third party systems

- Final testing and commissioning

- Complete after sales service and support

FUES (Hot Axle Hot Wheel Detection System)

Progress Rail is a major supplier of rail focused tag reading systems, and can design, supply, install, integrate and maintain the complete RFID tag system for global rail customers.

This article is a part of our September 2019 Magazine: Subscribe to our Magazine Today!