Geotechnical monitoring in tunneling and underground projects provides data that helps engineers and contractors in every stage of a project. Instruments are used to characterize initial site conditions, verify design assumptions and to monitor the effects of construction.

Each project presents a unique set of critical parameters. The designer must identify those parameters and then select instruments to measure them.

Ground conditions sometimes affect the choice of instrument. For example, a standpipe piezometer is a reliable indicator of pore-water pressure in soil with high permeability, but is much less reliable in soil with low permeability

Some popular Monitoring Parameters and Instruments:

Pore-water Pressure: This parameter helps engineers to: establish initial site conditions; predict slope stability; design and build for lateral earth pressures and monitor the effectiveness of drainage schemes.

Standpipe Piezometers, sometimes referred to as an open-hydraulic piezometer or a Casagrande piezometer, consists of a porous water-intake element connected to a riser pipe. Water enters the riser pipe through the intake element, which is normally sealed in the borehole at a specified depth. As pore-water pressure increases or decreases, the water level inside the standpipe rises or falls. Readings are usually obtained with a water level indicator, which provides a depth-to-water measurement.

Vibrating Wire Piezometers: These instruments consist of a tensioned steel wire, one end of which is anchored and the other end fixed to a diaphragm. The diaphragm deflects in response to applied pore water pressure, changing the tension in the wire and its resonant frequency. VW piezometers are typically used for continuous and long term pore pressure monitoring specifically in fine-grained soils where the use of conventional standpipe piezometers is not recommended.

Lateral Deformation: Measurements of this parameter help engineers to: evaluate the stability of slopes; monitor deformation of laterally loaded pile; monitor the magnitude and rate of movements in rock masses; check for ground movement that may affect adjacent buildings; monitor deformation of soil behind retaining wall and determine the need and timing for corrective measures.

The primary instrument for monitoring lateral, subsurface deformations is the Inclinometer. There are many types but one of the most commonly used is The traversing probe Inclinometer consists of a portable wheeled probe, graduated control cable, and a portable readout. With this system, the operator makes a survey of the borehole, taking tilt readings at two-foot intervals, from the bottom to the top of the casing to the top. The resulting data provides a detailed profile of the casing. If ground movement occurs, subsequent surveys will reveal changes in the profile. These changes can be plotted to determine the magnitude, depth, direction, and rate of ground movement.

Vertical Deformation: Measurements of this parameter help engineers to: verify that soil consolidation is proceeding as predicted; monitor heave in floor of Excavation; monitor settlement due to ground loss or heave outside of excavation; monitor for settlements that may damage buildings or service connections and determine the need and timing for corrective measures.

Some of the most important instruments to measure vertical deformation are: Settlement Cells (used to monitor a single, subsurface point); Settlement Extensometer (used to monitor large settlements in soft ground below fills); MultiPoint Rod Extensometers (provides high resolution multipoint measurements of vertical deformation) and Horizontal Inclinometer.

Single point instruments provide information needed to calculate movement of a single point. These devices include: Settlement cells; settlement points or single-point extensometers and settlement extensometer

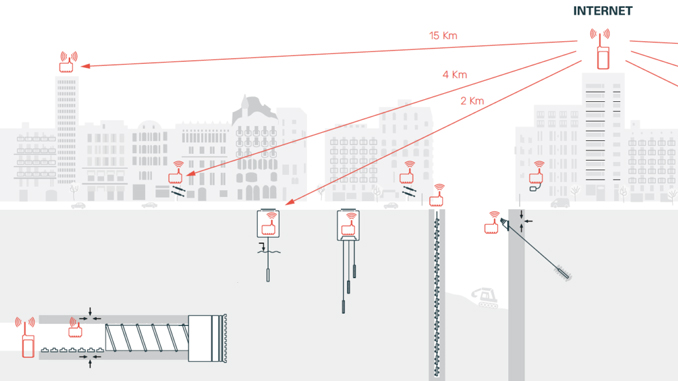

An automatic data acquisition system may be required when: there is a need for real-time monitoring and automatic alarms; Sensors are located at a remote site or in a location that prevents easy access; there are too many sensors for timely manual readings; qualified technicians are not available.

Author :

Mr. Keivan Rafie,

Lead Tunnel Engineer,

Stantec