SLTL Group took an initiative to triumph the challenges in the train coach manufacturing industry. The team learned the drawbacks of the existing manufacturing process and analyzed technical limitations of the conventional methods of operation. With expertise in laser technology, the team conducted a series of rigorous experiments to find the appropriate solution. Through the scientific research and tests conducted by the team it was concluded that Laser operations provide a better finish and comparatively higher strength in terms of manufacturing train coaches. The company started developing laser systems which could be very fast, efficient and reliable.

SLTL Group took an initiative to triumph the challenges in the train coach manufacturing industry. The team learned the drawbacks of the existing manufacturing process and analyzed technical limitations of the conventional methods of operation. With expertise in laser technology, the team conducted a series of rigorous experiments to find the appropriate solution. Through the scientific research and tests conducted by the team it was concluded that Laser operations provide a better finish and comparatively higher strength in terms of manufacturing train coaches. The company started developing laser systems which could be very fast, efficient and reliable.

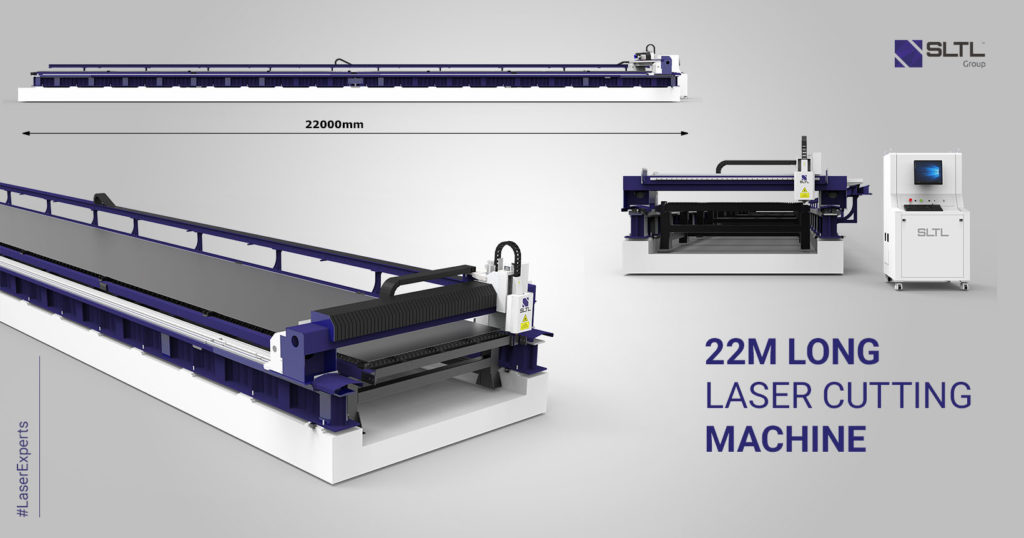

22-meter long laser cutting machine

As a result of the strong research and development, the team was able to put together the highest level of complexity in a machine which is staggering 24m long with 22m cutting bed size. The machine is made flexible to easily accommodate the metal sheet on the bed. With the excellent use of the engineering, the machine is rightly balanced to absorb the vibrations. The machine is equipped with cut through hardware and software components to have the fast and swift movement of the laser head, this allows the laser head to reach to the different spots quickly. Due to full automation, it also has lowered operating cost.

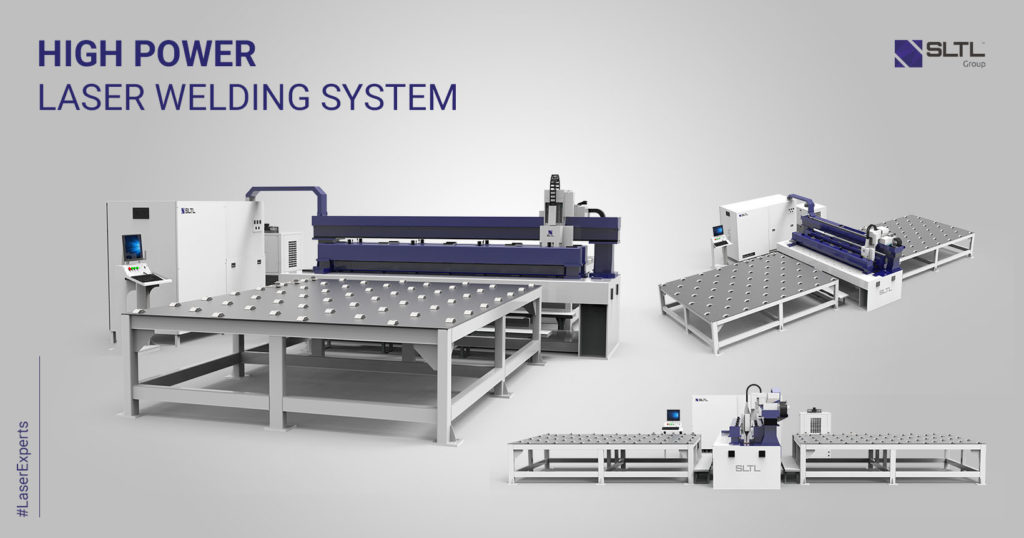

Train Bogie Laser Welding Machine

With all the experiments and the conclusions, the team at SLTL fundamentally manufactured, the first of its kind laser welding machine for train bogie. The laser welding operation then carried will provide continuous laser beam on the component and produces seamless weld line. The operation leaves minimum footprint and provides unparalleled strength to the resultant component. With machines like this Indian Railways are flourishing with excellent quality of built.

This article is a part of our June 2019 Magazine.