Plastics technology for the Railtrack

Woco Eisenacher Kunststofftechnik GmbH essentially focuses on fabrication of technical molded plastic parts, special technologies, such as two-component injection molding and vacuum conditioning, tool making with development of prototypes and 3D models in stereolithography, as well as measurement technologies, such as a 3D coordinate measurement machine, and a 3D scanner.

Reliable, international, customer-oriented – these three pillars allow Woco Group to secure its market lead in developing and manufacturing products that enhance the acoustic comfort and safety of vehicles and in creating components for industrial applications.

“Our customers’ global platforms provide us with ideas and set high standards for our organization,” says CEO Dr Hans Jürgen Kracht.

“We monitor market requirements and technological trends through our production sites worldwide, which also allow us to be closer to our international customers.”

The company’s headquarters in Bad Soden serves as its global center of competence and synchronizes its operations across the United States, Europe, Asia and the Nafta markets

The globally active Woco Group, with its headquarters located in Bad Soden-Salmünster, is a family-owned medium-sized company that achieved a turnover of 745 million euros with 6456 employees in 2018 in the automotive and nonautomotive market.

Woco focuses on Automotive with the core product fields of Powertrain and Polymer Technology. Powertrain Technology products improve acoustic comfort and so contribute to a reduction in fuel use. Polymer Automotive products insulate vibrations and provide sealings in the drivetrain and chassis and improve vehicle comfort.

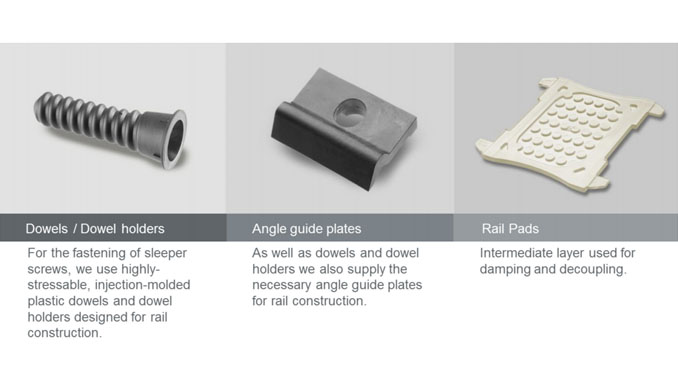

In the Non-Automotive area Woco concentrates on antivibration systems for rail technology and industrial applications, as well as on functional solutions for measurement, control and pipeline systems.

Woco products contribute to environmental relief through reduction of emissions and noise.

To serve the Indian market, Woco has two production facilities in India

Woco Tech Elastomere Noida Limited, Greater Noida

Woco Tech Polymere Kandla Limited, Gandhidham, Gujarat

Seeing enormous potentials in Asia’s automotive sector, Woco is keen on exploring opportunities in pipe systems and railway business to grow its customer base in the region.

Further information on website www.wocogroup.com

This article is a part of our June 2019 Magazine.