The Indian Government has set a capex target of Rs Rs 1.58 lakh corefor 2019 on Development of Railway Infrastructure. Dedicated freight corridors and high-speed corridors are also being planned which will entail heavy axle loads and will require stable foundations , good and stable track which increases the demand of new technology which help to give the best possible solution for the same.

As now railway lines are the main communication link between ports and major cities, the railways needs to be constructed through the coastal area and areas where the subgrade is poor and encounter with soft soil with high ground water table where it is necessary to improve the ground to increase the bearing capacity of soil and control the settlement of the railway embankments as per specified limits. Here in this article we will focus on construction of Railway embankment over soft soil using Prefabricated Vertical Drains.

As per Indian Railways “GUIDELINES ON SOFT SOILS- STAGE CONSTRUCTION METHOD “Soft clays are highly plastic fine grained soils with moderate to high clay fraction. They are characterized by high compressibility and low shear strength (generally less than 25 Kpa).

Construction of railway embankment onSoft soil conditions create several complexities for the designer and field engineer. When faced with the situation of constructing an embankment on soft subsoil, the following problems are encountered: Low shear strength, Stability of embankment, High compressibility, Settlement of embankment.

During the design of any embankments, Designer has to mainly focus to check on bearing capacity, settlement and overall stability. In case of embankment over soft soil it is necessary to improve the sub grade soil to increase the require bearing capacity and other related parameters. There are many ground improvement methods available now days, however, the engineering properties of the soft subsoil can be improved drastically using preloading with Prefabricated Vertical drains (PVD) over other conventional methods such as sand column, stone column etc.

Techdrain PVDs are used where preloading alone will not be efficient. Techdrain PVDs in soft clay accelerate the primary consolidation of clay since they bring about rapid dissipation of excess pore water pressure. Techdrain PVDs have no direct effect on the rate of secondary compression but the early completion of primary consolidation brings about the earlier onset of secondary settlement. Therefore the structures or embankments can be put to use earlier than it would be possible otherwise.

The accelerated rate of gain in shear strength of clay enables the loads to be applied more rapidly than would otherwise be possible. The effectiveness of Techdrain PVDs depends mainly on the engineering properties of soils, namely, soil permeability and coefficient of consolidation and their variations in space and time. Techdrain PVDs can be successful in accelerating the rate of consolidation of soft fine-grained soils. We would like to share similar case study as follows

Project Title: Rehabilitation of Railway track at Udaipur station yard in Agartala- Udaipur-Sabroom New B.G. Line (Ground Improvement for Railway Embankment with Prefabricated Vertical Drains (PVD))

Location: Udaipur, Tripura.

Material Used:Techdrain-Prefabricated Vertical Drain (PVD)

Manufacturer: Techfab India Industries Ltd

Project Completed: 2015

Project Brief: New Broad Gauge Railway embankment was being constructed between Agartala-Sabroom. Udaipur Station yard was situated on Agartala-Sabroom new railway line project at chainage 41-43. Earthwork for station yard started in Dec 2010, yard was located in marshy land and no ground improvement measures were adopted before constructing the embankment. Hence, failure of embankment had occurred at few locations in Sept 2011 and March 2012 respectively.

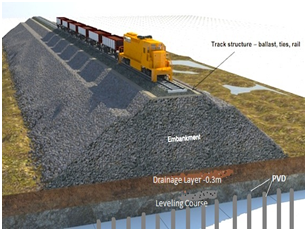

Figure 1. Left and Right side of the Embankment

Challenges: Railway station yard and Station building site are situated in low lying area previously known as Sukhsagar, consisting of poor quality soil up to 13.25m below ground level. During monsoon the whole catchment area was filled up with water and water table was raised even by 3.0 to 4.0 m above the ground level. Constructed embankment divided low lying area in two parts. Water used to flow from upstream to downstream through openings provided in the embankment.

Figure 2. Photographs of site locations

The drainage of nearby embankment was very poor. RDSO requested to suggest remedial measures in connection with failure of Railways embankment at Udaipur Station yard. Afterevaluating various ground improvement techniques; it was decided that Prefabricated Vertical Drain (PVD) is the best solution for accelerating consolidation and reducing pore pressure for the prevailing site conditions.

Ground Improvement by Installation of PVD:Soil had moderate swelling in nature and sub soil at depth below top of embankment had high swelling in nature. Therefore, consolidation of soil should be accelerated in order to reduce pore pressure and settlement.

Considering the project stretch, the depth of soft strata from bore log was considered up to 13.25m.For design and analysis, the soil was considered as fully submerged. For the stretches, where soft soil was encountered, 95% consolidation had to be achieved.

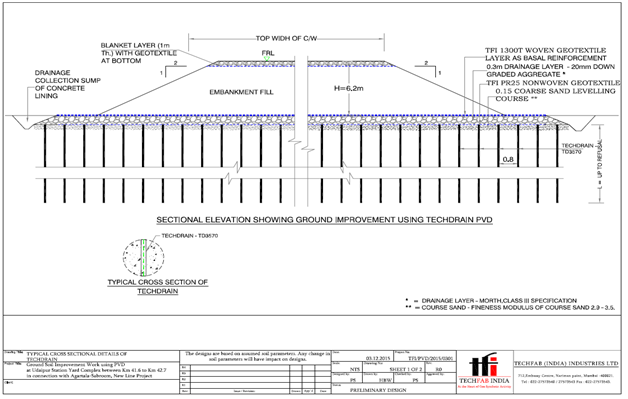

After design following section is finalized and approved by the authority.

Sectional Details Submitted for the Ground Improvement with PVD

Plan arrangement of Techdrain PVD proposed

A woven geotextile was installed at base to increase the overall stability of the embankment. This will also act as a separator between embankment fill and drainage layer. The drainage layer was installed to be of 30cm along with an additional layer of non-woven geotextile as shown in the cross section. All layers starting with 15 cm of sand layer, layer of nonwoven geotextile, 30 cm thick drainage layer followed by layer of woven geotextile was proposed to be installed. It was decided to install settlement gauges and piezometers in order to monitor the consolidation process.

Consolidation of Soil: As calculated, time required for 95% consolidation of foundation soil was 143 years; which is too long therefore needed to consider installation of Techdrain (PVD) to minimize time required for adequate consolidation. When it was considered provision of TechdrainPVD at 0.8m spacing, time required for 95% consolidation was reduced to 3.31 months (100 days).

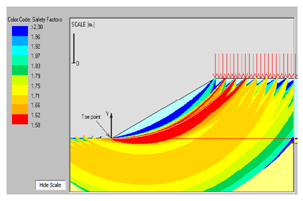

Slope Stability Analysis : Slope stability analysis for side slope was carried out by Slope-W for effective ht of 6.2m, the factor of safety works out to be 1.47 which is more than required 1.4 as per 2.1 of Annexure III of “Guidelines for Earthwork in Railway Projects”, July 2003.

Rotational Stability Analysis: Rotational stability analysis was carried out for various critical circles and Factor of safety calculated was 1.58. Fig shows rotational stability analysis done by software.

Settlement Analysis of Sub Soil: Settlement analysis was carried out as per laboratory test results of GE lab RDSO. As per details of bore logs up to hard strata provided by client, 13.25m of compressible layer was considered and detailed calculation was carried out. Settlement of soft clay comes out to be 1.2m. When improved with PVD at 0.8m spacing, embankment constructed with rise of 0.6m at every stage. Stage wise construction and corresponding estimated settlement was provided.

Conclusion:

As the embankment was constructed over weak soil and had already failed, it was understood to go for detailed geotechnical investigation and provided suitable ground improvement technique based on the report.

TechFab had proposed ground improvement with PVDs and geotextiles – with detailed calculations, plan & section drawings and stage wise construction sequence with estimated settlement and SBC checks. The solution was scrutinized by IIT approved and accepted by authority.

The ground improvement was executed on site as per approved scheme along with proposed instrumentations and had performed successfully for the intended purpose with satisfactory results.

Therefore, itcan be said that, for locations with very weak soft clay for higher depths, PVDs can be feasible and effective solutionto reducing time required for consolidation and accelerate the settlement.

Written by

Namrata Bichewar

Engineer -Business Development , Tech Feb (India) Industrise Ltd.