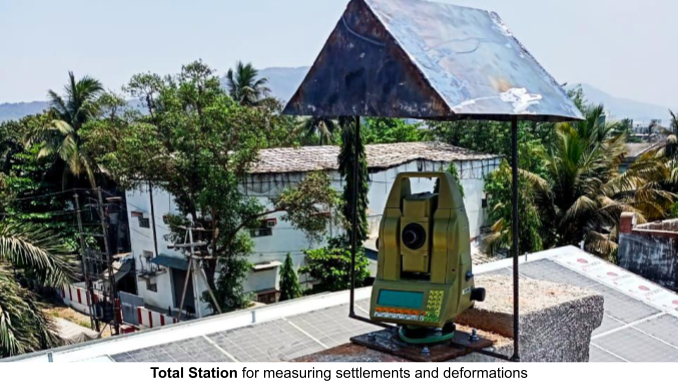

The National High-Speed Rail Corporation Limited (NHSRCL) is elevating safety standards across the Maharashtra section of the Bullet Train corridor by installing state-of-the-art Geotechnical Monitoring Instruments. These instruments are crucial for protecting civil structures and service utilities during the extensive construction activities.

More Details:

Highly sensitive Geotechnical Monitoring Instruments are being deployed to ensure safety of civil structures and service utilities, at and around the construction sites in Maharashtra for the Bullet Train corridor by the National High-Speed Rail Corporation Limited (NHSRCL).

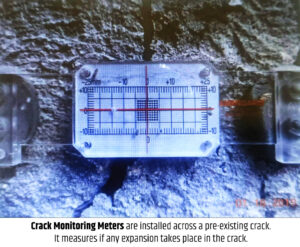

Various types of Geotechnical Instruments like Inclinometers, Vibration monitors, Ground settlement markers, Tilt metres etc. have been installed at and around construction sites for monitoring tilt, settlement, vibration, cracks and deformation. These instruments play a crucial role in making sure that neither there is any risk to ongoing underground works like excavation and tunnelling nor to the structures surrounding the site.

24 X 7 Geotechnical Monitoring:

- The Geotechnical Instruments are connected to their respective modules to record and monitor the activities.

- This allows on-time identification of potential risks and enables timely interventions to mitigate them.

- The dust and noise monitors are also being installed at construction sites, to ensure that the noise and air pollution remains in the permissible limit at and around construction sites.

Works in Progress:

- The construction activities are in progress for the 21 km long underground portion of Bullet Train corridor in Mumbai and Thane districts in Maharashtra.

- The works include excavation for about 1 km long and 32-metre-deep (around 10 story inverted building) underground Bullet Train station at Bandra Kurla Complex, construction of shafts and portals for tunnelling works.

- Three mega Tunnel Boring Machines (TBMs), will be deployed for 16 km tunnelling work, which includes 7 km under sea tunnel and remaining 5 km of the tunnel will be made by using New Austrian Tunneling Method.

- The depth of the tunnel will vary from 25 metres to 57 metres. Three Shafts, one ADIT and a portal are being constructed for lowering Tunnel Boring Machines.

- The construction of such underground megastructures demand safety of the construction sites, surrounding structures above as well as below the ground with the least inconvenience or disruption to the people residing in the vicinity.

Conclusion:

The installation of advanced Geotechnical Monitoring Instruments by NHSRCL exemplifies their dedication to safety and environmental care in constructing the Maharashtra Bullet Train corridor, ensuring minimal disruption and maximum protection for nearby communities.

Source: NHSRCL – Press Release | Images Credit: NHSRCL

Join us for the upcoming 5th Rail & Metro Technology Conclave with 700+ Top Rail & Metro Industry Leaders on 23rd & 24th July, 2024 in New Delhi, India. Register here and participate in the summit.