Article Source – Fluid Controls: Our engineering and design strength have ensured that millions of Fluid Controls connectors have been successfully installed on electric and diesel locomotives, motorized coaches and metro cars, providing “fit and forget” assurance to customers.

Fluid Controls®

has over 40 years of experience in engineering connections for rail & metro brake piping assemblies. We offer customers total solutions for the locomotive, coach, and metro brake piping arrangements – from design & engineering services to supply of high performance connectors and installation services.

We partner with customers to be a single source supplier for various connectors required for rail and metro applications. Our products include :

- Double Ferrule Fittings with multiple sealing points and high vibration resistance.

- DIN Single Ferrule Connectors.

- Bulkhead and Threaded Adaptors.

- FlexiGrip Connectors for misaligned pipe connections.

- Quick Release Connectors.

- Customized connectors designed to clients’ requirements

- Isolating Cocks and Clamping Accessories (DIN and customised).

With our composite expertise of manufacturing connectors, our understanding of tube and end connector performance and our decades of experience of swaging and accurate tube bending, we now offer customers a complete end-to-end engineered supply and installation solution. Our engineered installation services include :

- On-site Connector Fitment Services: our expert resident team provides swaging services and ensures proper fitment of ferrules and performance of the connector.

- End-to-end Installation Services: includes supply of connectors and on-site installation of brake pipelines on the shell underframe and bogie, including tube formation, connector fitment, mounting of piping and leakage testing.

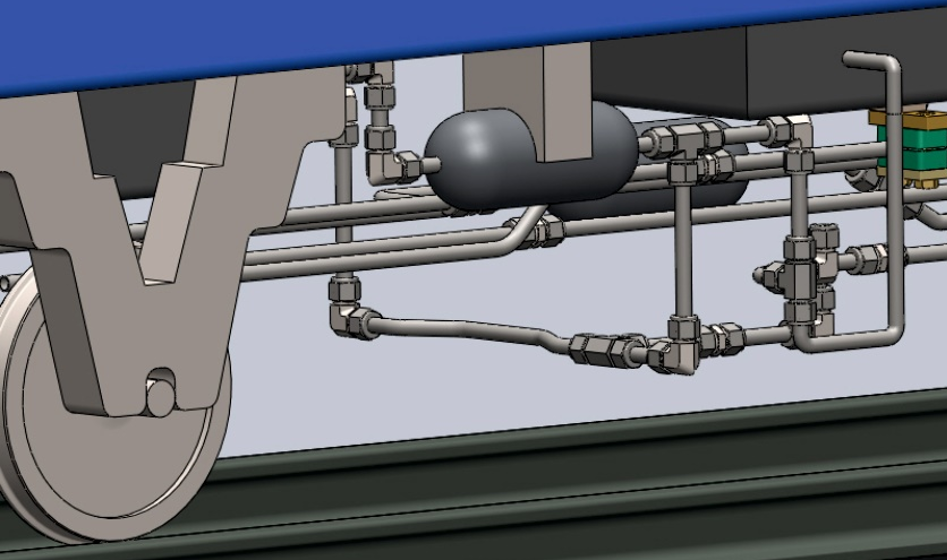

- Pre-piped Assemblies: This begins with engineering support during the designing of the brake piping layouts supported by 3D modeling and FEA. The tube formation and end formation and swaging of connectors is done at our facility and the pre-piped assembly is shipped to the customer site. If required, Fluid Controls® team provides on-site fitment of these assemblies. These pre-piped assemblies facilitate customer inventory management and ensure faster turnarounds.

Fluid Controls® 3D Schematics for Coach Installation

Fluid Controls® is headquartered in Mumbai with a manufacturing facility at Pune, Western India, where we have a state-of-the-art R&D center, which offers clients customized solutions based on analytical formulations, 3D Modelling, and FEA. Today, we are recognized by the Department of Scientific & Industrial Research (DSIR) as an “In House R&D Unit”

This article is a part of our June 2019 Magazine.