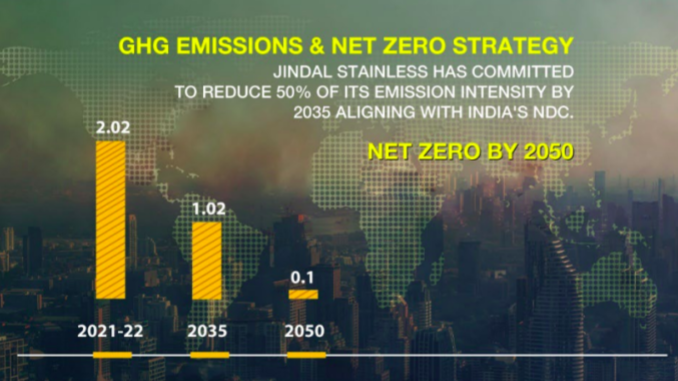

Jindal Stainless Limited (JSL) said it is set to achieve a mid-term target of 50% carbon emissions reduction well before the target year of 2035. The company invests INR 700 crores in various sustainability projects aimed at reducing 1.5 million tonnes of carbon emissions every year.

More Details:

- Jindal Stainless Limited (JSL), India’s largest stainless steel manufacturer, said it is set to achieve its mid-term target of 50% carbon emissions reduction well before the target year of 2035, as it marked its presence at the prestigious United Nations Confederation of Parties (COP) 28 climate summit for the first time.

- The company was invited by the Ministry of Steel, Government of India to showcase its decarbonisation initiatives at a side event organised by the Ministry of Steel, Government of India at the India Pavilion in Dubai.

- The Ministry of Environment Forest and Climate Change (MoEFCC) was assigned as the nodal ministry for the event titled ‘Forging a carbon-free future: The Indian Steel Sector’s Transition’ on Day 6. This coincided with the thematic day of ‘Energy, Industry/ Just Transition/ Indigenous Peoples’ of the global platform.

Mr. Abhyuday Jindal, Managing Director, JSL said, “We are privileged to have been invited by the Indian government for the COP28 event. We are proud of our decarbonisation efforts, and an event of this stature is an opportune moment to reaffirm our global commitments. We are investing INR 700 crores in various sustainability projects aimed at reducing 1.5 million tonnes of carbon emissions every year. We are helping in building a modern, sustainable world with the best-in-class technology, innovation, and investment in R&D in order to meet the evolving customer requirements to offer high-class stainless steel solutions.”

Chief Sustainability Officer Mr. Kalyan Bhattacherjee, while addressing the event, spoke about the company’s efforts in establishing low carbon pathways as leading players in a hard to abate sector. We have undertaken several measures, including internal improvements and tie-ups with external partners, to reduce our carbon footprint. We’ve strategically aligned our decarbonisation initiatives to meet the goal of Net Zero by 2050. We have also introduced digitalisation for sustainability data management through a unique ESG digital platform, which automatically collects production, energy, material consumption and carbon emissions-related data directly from our ERP system SAP S4 HANA. This helps in accuracy and transparency of GHG accounting and reporting. We are actively addressing our Scope 3 environmental, social and governance (ESG) compliance through Sustainable Procurement, Logistics Decarbonisation and circular economy.

The company signed an MoU with Renew Power for a 100 megawatt (MW) wind-solar hybrid renewable energy (RE) round-the-clock (RTC) project, due for commissioning in 2024. Other RE RTC projects underway will help the company achieve an overall capacity of 300 MW hybrid RE. These projects along with the green hydrogen plant will be game-changing in achieving the midterm targets as the level of carbon emissions will begin to decline once the projects are integrated.

Heads of States, negotiators, and officials from nearly 200 countries converged at the COP 28, also known as the UN Climate Change Conference, which is being held in the United Arab Emirates from November 30 to December 12, 2023.

About Jindal Stainless:

- India’s leading stainless steel manufacturer, Jindal Stainless, has an annual turnover of INR 35,700 crore (US $4.30 billion) in FY23, and is ramping up its facilities to reach 3 million tonnes of annual melt capacity in FY24.

- It has two stainless steel manufacturing facilities in India, in the states of Odisha and Haryana. Jindal Stainless has a worldwide network in 15 countries and one service centre in Spain. In India, there are 10 sales offices and six service centres.

- The company’s product range includes stainless steel slabs, blooms, coils, plates, sheets, precision strips, blade steel and coin blanks. Integrated operations have given Jindal Stainless the edge in cost competitiveness and operational efficiency, making it one of the world’s top five stainless steel players (ex-China).

- Founded in 1970, Jindal Stainless continues to be inspired by a vision for innovation and enriching lives and is committed to social responsibility. The company boasts an excellent workforce, value driven business operations, customer centricity and the best safety practices in the industry.

- JSL remains committed to a greener, sustainable future, fuelled by environmental responsibility. The company manufactures stainless steel using scrap in an electric arc furnace, the least greenhouse gas emission route since it enables 100% recyclability with no reduction in quality, thereby achieving a circular economy.

- The company aims to reduce carbon emission intensity by 50% well before FY 2035 (from FY 2022 baseline levels of 1.91 tonnes CO2/tonnes of crude steel) and achieve Net Zero by 2050.

Source: JSL- Press Release | Image Credit: Jindal Stainless Limited