RITES Ltd. has invited for and on behalf of Dedicated Freight Corridor Corporation of India Limited (DFCCIL), online bids in two packet systems from eligible tenderers for the following work.

- Tender Reference Number: RITES/CO/WS/DFCCIL/OMRS/2021

- Name of Project: Supply, Installation, Commissioning & Annual Maintenance & Operation Contract (AMOC) for a period of 5 years for Online Monitoring of Rolling Stock (OMRS) consisting of Acoustic Bearing Detector (ABD) and Wheel Impact Load Detector (WILD) on Dedicated Freight Corridor (DFC) of Dedicated Freight Corridor Corporation of India Limited (DFCCIL), New Delhi.

- Estimated cost of the contract: INR 66.52 Crore

- Period Of Work(Days): 730

- Document Download / Sale Start Date: 13-Feb-2021

- Document Download / Sale End Date: 01-Mar-2021

- Bid Submission Start Date: 22-Feb-2021

- Bid Submission End Date: 01-Mar-2021

- Bid Opening Date: 01-Mar-2021

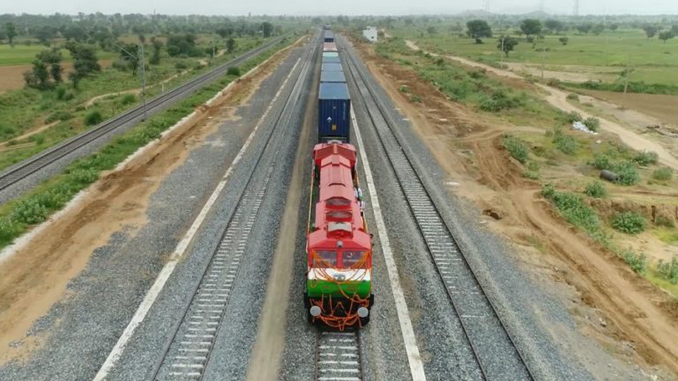

Dedicated Freight Corridor Corporation of India Ltd. (DFCCIL), a PSU under Ministry of Railways, created to undertake a primarily double-line corridor for running trains at maximum permissible speed of 100 kmph to cover approximately 3,300 route km. Eastern Corridor (about 1839 kms) from Ludhiana to Dankuni (West Bengal) and Western Corridor (about 1534 kms) from Jawaharlal Nehru Port, Mumbai to Dadri (UP) along with inter linking of two corridors at Dadri.

- The Dedicated Freight Corridor (DFC) Project entails construction of railway tracks capable of handling 25 ton axle load initially and 32.5 ton axle load eventually and longer trains.

- DFCCIL has planned to develop a system of data acquisition & analysis comprising of Eleven Units of Acoustic Bearing Detection (ABD) and Wheel Impact Load Detection (WILD), with a provision to integrate other equipment in future installed at various locations on DFCCIL network. This system is called the Online Monitoring of Rolling-stock System (OMRS).

- The System shall monitor the health of each rolling stock of the train in order to identify defects in bearing and in wheel. Defect report generation and alert communications shall occur on “real-time” bases. The proposed system shall focus initially on bearing defects and wheel impact and be capable of:

- Identification and classification of bearing faults for BG rolling-stock: locomotive, coaches and wagons axle wise starting from the first axle of the locomotive and map it to the unique vehicle id.

- The identification and quantification of wheel impact, calculation of Impact Load Factor caused due to wheel flats etc. axle wise starting from the first axle of the locomotive and map it to the unique vehicle id.

- Software, hardware, data management system for integration, storage, analysis and trending of data streams generated by passing train, relevant communication link to the Central Processing unit and IT hardware at the Central Processing and Storage unit.

- The system should make available data generated by the wayside detectors and other sensors on the web through a dedicated secure website as well as the Internet. Detailed Reporting as per DFC requirements should be possible. The website database shall be capable of interfacing with DFCCIL intranet and integrating reports from the existing WILD/ABD systems of DFCCIL. The site for installation of ABD/WILD field equipment would be on a single line or double line BG section of the DFC network. The system should function in either direction of movement. The train speeds will be in the 30-160 Kmph range. Both passenger and freight trains will be moving on the section, hauled by single or multiple Diesel Electric or Electric locomotives.

Scope of Supply:

Supply, Installation, Commissioning & Annual Maintenance & Operation Contact (AMOC) for a period of 5 years for On Line Monitoring of Rolling Stock (OMRS) consisting of Acoustic Bearing Detector (ABD) and Wheel Impact Load Detector (WILD) on Dedicated Freight Corridor (DFC) of Dedicated Freight Corridor Corporation of India Limited (DFCCIL), New Delhi as per details given below:-

- Wayside data collection equipment comprising WILD and ABD with requisite cabling – one per location (11 sets).

- Equipment Hut with necessary instrumentation and software for acoustic signature analysis of bearing detection and wheel impact detection and integration with other data stream including vehicle identification, network data connectivity software, provision for online UPS, Media Convertors or routers for fiber cable connection, Lighting arrestor and earthing – One per site (Total 8 sets).

- Cabling with duct for connecting equipment hut to the Power supply provided by DFCCIL to data network points given by DFCCIL at the site, foundation of site equipment, security arrangements, facilities and signages – One per site (Total 8 sets).

- Audio-Visual Alarm node with 500 VA UPS and LAN patch-up equipment for connecting the DFC OFC network to the nearest DFC Divisional Office and to the DFC Head Quarters with facility for real time alarms- 11 sets.

- Central Control with necessary software, database, network data connectivity infrastructure to OFC network and Internet, provision for network security and monitoring, large display system, Signage and furnishing – Two sets, one each for Western DFC and for Eastern DFC

- Comprehensive Annual Maintenance Operation of OMRS for 5 years including warranty period of 3 years. The AMOC rates are to be quoted on a yearly basis, giving the rates for each year. This will be inclusive of all spares, material and labour costs – for a complete system covering 11 sets and all associated equipment mentioned in this clause 1.2.

- Comprehensive Annual maintenance operation (AMOC) for further 10 years after conclusion of initial period of 05 years. These AMOC rates are to be quoted on yearly basis, giving the rates for each year. This will be inclusive of all spares, material and labour costs – for complete system covering 11 sets and all associated equipments mentioned in this clause 1.2. DFCCIL reserves the right to extend the AMOC period for a further 10 years before completion of the initial 5 years AMOC period, based on the performance of the successful tenderer, as per rate indicated in the offer.

- Training, as per clause 1.7 of this section

- Camera based identification system PVIS (Photographic Vehicle Identification System) at each of site – 01 per line (Total 11 sets).

- Some of the double line sections will have two data acquisition units, one for each of the line. Tentative list of installation is enclosed at Annexure B.

- The Central control for Eastern DFC will be situated in Prayagraj (Allahabad) and for Western DFC at Ahmedabad at the location provided by DFC. The Central Control building will be provided by DFC. Electrical cabling, optic fibre cabling, furnishing and fixtures at the

- control centre are in the scope of tenderer. Display Units, server, UPS are to be provided at the DFCCIL Headquarters.

- Both power and communications cabling to the nearest point of patching with DFC circuit (which will be approximately within 1 km from the site) has to be provided by the tenderer.

The bid forms and other details can be obtained from the website http://ritesltd.com/ and CPP portal https://etenders.gov.in/eprocure/app.

Source: RITES-Tender | Image Credit: DFCCIL