The National High-Speed Rail Corporation Limited (NHSRCL) has adopted a groundbreaking approach to track installation for the Mumbai-Ahmedabad Bullet Train project, leveraging cutting-edge machinery and mechanised processes.

More Details:

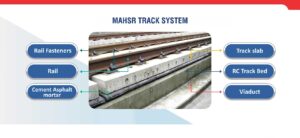

The Mumbai-Ahmedabad Bullet Train project will have a J-Slab track system based on the Japanese Shinkansen track system. This is for the first time, the J-slab ballastless track system is being used in India. For 352 km of alignment in Gujarat & DNH, 704 km of track is to be laid on viaduct and two Bullet Train depots at Sabarmati and Surat.

The entire process of track installation is mechanised with cutting edge machinery especially designed and manufactured as per Japanese specifications. Taking the initiative under Make-in-India (MII) policy, some of the machines are now being manufactured in India also. The track laying work in Gujarat is progressing well.

More than 35,000 MT of rails and three sets (03) of track construction machinery have been received at Surat and Vadodara for the project. The fleet of machines include rail feeder car, track slab laying car, CAM laying car and flash butt welding machine, whic will be used for track construction works. The assembly, testing and commissioning of these machines is in progress.

More than 35,000 MT of rails and three sets (03) of track construction machinery have been received at Surat and Vadodara for the project. The fleet of machines include rail feeder car, track slab laying car, CAM laying car and flash butt welding machine, whic will be used for track construction works. The assembly, testing and commissioning of these machines is in progress.

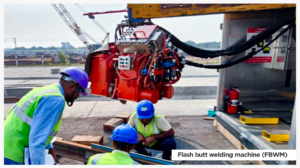

Flash butt welding machine (FBWM):

- The 25 m long 60 kg rails are welded using Flash butt welding machine (FBWM) to form 200 m long panels near the TCB (track construction base) over the viaduct.

- Total 3 FBWM have been procured till now, and the same have to pass through stringent approval methodology prior to commencement of Rail welding fit for allowing high speed train running at 320 kmph.

- The training for rail weld finishing and rail weld testing have been completed by the JARTS.

Track Slab Laying Car (SLC):

- Precast track slabs are lifted onto the viaduct, loaded on specially designed SLC and moved to the track laying location. By using SLC, which can pick 5 slabs at a time, track slabs are laid in position on the RC track bed. 3 SLC have been arranged for slab laying work.

Rail Feeder Car (RFC):

- 200 m long panels are fed and laid over RC track beds using Rail Feeder Car. RFC will push the rail pair over the RC bed and a temporary track will be laid initially on RC. Total 4 RFCs have been procured till now.

Cement Asphalt Mortar Injection Car (CAM Car):

- After placement of track slabs at proper place on the RC Bed, CAM cars run on the parallel track. This CAM car mixes the ingredients for CAM mix in design proportion and this CAM mix is injected under the slab to achieve the required line and level of track. 2 CAM cars have been procured till now.

Source: NHSRCL – Press Release | Images Credit: NHSRCL

Join us for the upcoming 5th Rail & Metro Technology Conclave with 700+ Top Rail & Metro Industry Leaders on 23rd & 24th July, 2024 in New Delhi, India. Register here and participate in the summit.